Our manufacturing processes

From creation to finishing

We master all the trades required to produce your products in small and medium series. Thus, from the raw metal to the completely finished work, we manufacture the products to the desired level of finish.

Design

Modeling

Catering

from a plan or a piece to be reproduced that you entrust to us, our work consists of creating or modelling a master piece that can be used

Manufacturing

Moulding

the mould making process is chosen according to the complexity of the part. The “beaten clods” technique, which is lost today, is regularly used when the shapes show undercuts. Our processes are detailed here

Casting

Casting is an exceptional moment when all the gestures are precise and delicate. A few moments later, the casting can finally be seen in its raw state

Completion

once the part has been cast, cooled and stripped, multiple steps consist of cutting, sanding, deburring, grinding, machining, hammering, welding, assembling… so that the material gradually approaches the desired final shape.

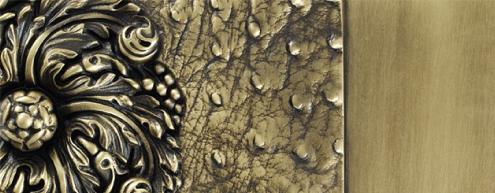

Finishing

to give it the desired appearance, the finishing consists of polishing, then varnishing or carrying out a surface treatment (chrome-plating / nickel-plating / gilding) or a patina on the product to give it the desired appearance.

The metals worked

The Polymeto foundry works with noble materials such as bronze and brass, sometimes silver.

Bronze and furniture bronze (brass) are copper metals which have the peculiarity of resisting extremely well to the passage of time.

The shades:

- Bronze: UE5, UE7, UE10

- White bronze

- Bronze (other shade on request)

- Brass: 65/35, 60/40

- Tombac, lead-free brass

- Silver and other metals on request

Most of our work is carried out by hand by skilled workers trained by us.

Our production tool

From the preparation of the moulds, to the casting, then to the machining and finishing of the parts, our production tool enables us to carry out each of the manufacturing stages, and gives us the flexibility needed in today’s foundry.

Most of our work is done by hand. For sand casting and lost-wax casting, the workers make the precise detail impressions into which the metal will be cast.

Precise machining by hand and using conventional or numerically controlled machine tools, as well as welding and assembly are carried out by our skilled workers who we train in-house.

Only the processing is carried out by partner craftsmen we have a special relationship with. During the finishing process, a final quality control is carried out before the products are dispatched to all continents.

Our manufacturing processes

Natural sand casting

The oldest and most widely used process in the Polymeto foundry, it requires meticulousness and know-how that only experience can provide. A mixture of clay and sand from quarries, it allows the reproduction in small series of medium sized and complex shaped pieces. The advantage is that the sand is recycled to make the following parts.

Lost-wax casting

Used when the shapes are extremely complex and the details very fine, lost-wax casting requires a lot of time and attention to detail. The steps prior to casting are more tedious, with the benefit of almost no finishing touches. Once again, knowledge here is gained through experience. It is also a very old process, which has been used for centuries in the jewellery industry. It is increasingly used in industry where other processes cannot provide solutions. Polymeto masters this process to offer the best and be able to meet the most difficult demands.

Resin sand moulding

This newer, chemically set moulding is simpler. A mixture of pure silica sand and catalysed resin, it is more resistant and allows the production of heavy or voluminous parts. Although easier to work with, the precision of the parts is slightly less than with natural sand.

Shell moulding

a process requiring specific tooling makes it easier to produce certain items. Adapted for larger quantities and small parts, it is no longer suitable when the details are too precise.

THE PARTICULARITY OF OUR FOUNDRY IS THAT IT IS ABLE TO DELIVER YOU

FINISHED PARTS DOWN TO THE LAST DETAIL

Finished or semi-finished part

Completion

Our craftsmen offer to manufacture your parts up to the desired stage of completion: rough casting, semi-finished (ground, polished, assembled), or with the desired surface treatment.

- deburring, grinding

- assembly

- welding

- drilling, tapping

- machining, turning, milling

- grinding, polishing

- surface treatments

By offering this possibility of complete finishing, Polymeto provides a service unequalled in today’s high-end foundry. As the sole interlocutor for their project, Polymeto simplifies the follow-up and frees up precious time for its customers for the creation of new models.

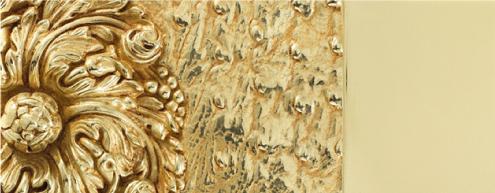

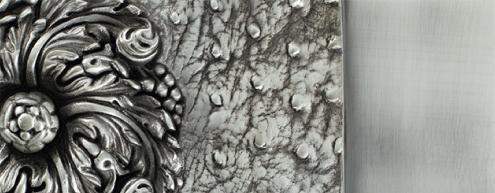

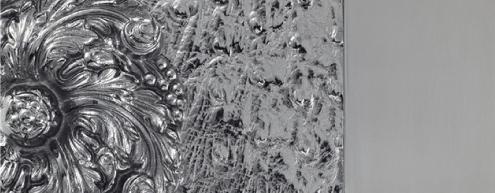

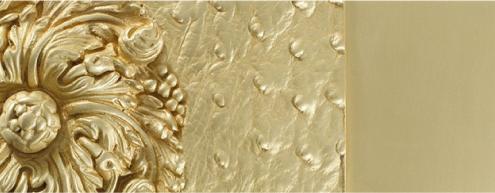

Our finishings

AR – silver

DOR – 24 carat gold plating

NBB – Brushed bright nickel

NM – matt nickel

PV – varnished polished

PVP – patina varnished polished

VAG – old silver

CH – chrome

NB – bright nickel

NBS – shiny nickel satin base

NN – black nickel

PVO – polished varnished gold colour

SBV – scotch brite matt varnish

VB – old bronze

Find us on social networks

Fonderie Polymeto

556 rue de Belloy

80130 Bourseville

Téléphone

+33 (0)3 22 30 01 05

contact@polymeto.fr